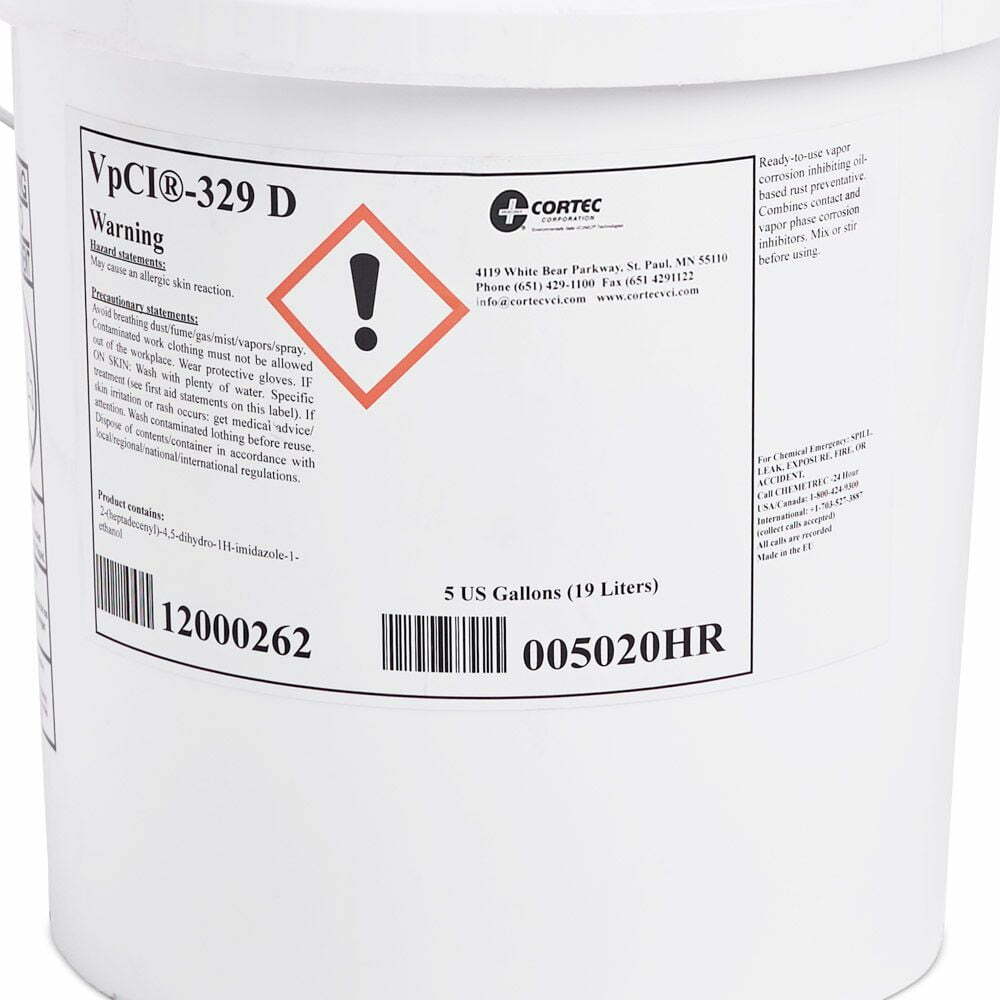

Cortec VpCI® 329 & 329 D Corrosion Inhibitor Oil 5 (19 ltr) & 55 (208 ltr) Gallon Drums

Cortec VpCI® 329 & 329 D Corrosion Inhibitor Oil 5 (19 ltr) & 55 (208 ltr) Gallon Drums

Couldn't load pickup availability

Cortec® VpCI® 329 is a best in class corrosion inhibiting oil perfect for use with lubricating, hydraulic and preservation oils.

Available from stock Cortec VpCI 329 is also available in D, F, ES & SC special formulations. VpCI 329 & 329 D are available from stock in 5 gallon (19 ltr) & 55 gallon (208 ltr) drums.

Cortec VpCI 329 is a vapour corrosion inhibitor oil ideal for use with other lubricative, hydraulic & preservation oils.

Cortec VpCI 329 is a concentrated corrosion inhibitor oil that can be used both indoors and in sheltered outdoor conditions. The vapours from the patent pending VpCI corrosion inhibitor formula.

VpCI 329 uses a dual action by creating both a film of corrosion inhibitors which guard the metal surface, whilst the vapour molecules atomise into the surrounding air above the oil itself.

This impressive combination offers complete corrosion protection for systems and their internal component parts.

Cortec VpCI 329 Features

- Free from harmful chromates, nitrates & phosphate inhibitors.

- High flash & fire tolerances.

- Multi metal protection including zinc, galvanised steel, aluminium, copper and brass.

- Can be used with most oils.

- Can be misted/fogged into hard to reach compartment spaces.

- Parts can be dipped before storage.

- VpCI 329.

- NATO part number # 6850-66-132-6100 / NSN # 6850-01-470-3359.

- VpCI 329 conforms to mil-prf-46002 grade 1 equivalent.

Cortec® VpCI 329-D, D ES, F & SC

VpCI-329 D is a ready to use rust preventative oil formula. It’s great for metal surfaces that only require a thin coat of oil before finishing, storage or further processing.

Effective on gears, coils and other metal parts that use oil for protection.

VpCI 329-D Features

- 329 D performs well under adverse conditions (up to 100% humidity).

- Works in the presence of corrosive substances such as chlorides, hydrogen sulfide & other sulfur based chemicals.

- Thermally stable providing long term corrosion protection upon contact.

- VpCI 329 can be applied by spray, dipped, brushed or rolled onto metal surfaces.

- Choose VpCI 329 D ES for hand held trigger applications.

VpCI 329 F Features

- VpCI-329 F is approved for use by the US department of Agriculture (USDA) as an accepted oil based concentrate for use as an additive in combination with lubricants and hydraulic oils.

- VpCI 329 F is a ready to use corrosion preventative fluid.

- Approved for use on packaging materials in indirect contact with meat and poultry.

- Conforms with FDA CFR 178 3300.

VpCI 329 SC (super-concentrate)

- Is highly concentrated reducing shipping & storage costs.

- When combined with VpCI-329 SC treated oils will conform with mil-p-46002 & MIL C 16173D Grade 3.

Product Specifications (.PDF)

Frequently Asked Questions

• What exactly is Cortec VpCI-329 and how does it prevent rust?

Cortec VpCI-329 is an oil-based, concentrated vapor corrosion inhibitor designed to protect metals from rust. It works in a rather clever dual-action way: first, it forms a tenacious film that clings to the metal surface, offering direct contact protection. Second, it releases special vapor phase inhibitors into the air above the oil, which then condense and form a protective barrier even on metal surfaces not in direct contact with the oil. This means you get comprehensive protection for all internal system parts.

• Is Cortec VpCI-329 a ready-to-use product, or does it need to be mixed?

Cortec VpCI-329 is actually a concentrate, so it generally needs to be diluted with lubricating, hydraulic, or preservation oils before use. However, there is also a "D" (diluted) version available from Valdamark Direct, which is ready to use for certain applications.

• What types of metals can Cortec VpCI-329 effectively protect?

This versatile corrosion inhibitor is designed to protect a broad range of metals, including ferrous metals, zinc, galvanized steel, aluminum, copper, and brass. It's quite comprehensive in its coverage.

• Can Cortec VpCI-329 be used in outdoor conditions, or is it strictly for indoor use?

Cortec VpCI-329 provides excellent corrosion protection in both sheltered outdoor and indoor conditions. So, if you're looking to protect equipment that might be stored outside but under some cover, this product is a good fit.

• How does the "vapor phase" technology in Cortec VpCI-329 actually work to prevent rust in enclosed spaces?

The "vapor phase" part of VpCI technology means that the corrosion inhibitors in Cortec VpCI-329 actually vaporize and travel through the air within an enclosed space, like a gearbox or an engine. These vapors then condense on all exposed metal surfaces, forming a protective molecular barrier that stops rust from forming, even in areas the oil itself might not directly reach.

Relevant products you may want to consider:

• I need to protect metal parts before long-term storage. How should I apply Cortec VpCI-329?

For storing individual metal parts, you can easily apply Cortec VpCI-329 by spraying, dipping, or brushing it onto the surfaces before they go into storage. This ensures a consistent protective layer.

• What's the best way to use Cortec VpCI-329 for protecting internal engine components during lay-up?

When preparing engines for storage or lay-up, you should add Cortec VpCI-329 directly to the oil in the engine. For optimal results, it's recommended to cycle or run the engine for about 10 minutes after adding the VpCI-329 before shutting it down. This helps circulate the protective agents throughout the system.

• Can I just leave Cortec VpCI-329 in the oil once an engine is back in operation, or does it need to be removed?

One of the great advantages of Cortec VpCI-329 is that there's no need to remove it from an operating engine after storage. The engine can simply be operated normally, which saves a significant amount of time and effort.

• What are the recommended dilution ratios for Cortec VpCI-329 based on the desired protection duration?

Valdamark Direct highlights clear dilution guidelines: for short-term protection, you'd use one part VpCI-329 to 19 parts oil. For medium-term protection, it's one part VpCI-329 to 9 parts oil. If you need long-term protection, the ratio is one part VpCI-329 to 4 parts oil.

• Is there a specific way to prepare the Cortec VpCI-329 before mixing or application?

Yes, before each use, it's important to agitate the product. This ensures the concentrate is well-mixed and ready to deliver its full protective power.

Relevant products you may want to consider:

• Beyond engines, what other systems can benefit from Cortec VpCI-329 during storage or mothballing?

Cortec VpCI-329 is an excellent choice for preventing rust inside gearboxes that are going to be stored idle for extended periods. It's also highly effective in lubricating, hydraulic, and metal cutting systems during their storage or mothballing phases.

• Can Cortec VpCI-329 be "fogged" into large metal compartments for protection?

Absolutely! Cortec VpCI-329 can indeed be fogged into metal compartments. This method allows the vapor phase inhibitors to reach and protect internal system parts that might be difficult to access otherwise.

• What makes Cortec VpCI-329 stand out from other corrosion inhibiting oils?

Its unique dual-action protection, combining a tenacious film with vapor phase inhibitors, really sets it apart. This ensures comprehensive protection even in areas not directly coated, something many conventional oils can't achieve.

• Is Cortec VpCI-329 compatible with most common oils, or are there specific types it should be used with?

One of its practical benefits is its compatibility with most lubricating, hydraulic, and preservation oils. This makes it a flexible choice for various industrial and commercial applications.

• Does Cortec VpCI-329 contain any harsh or hazardous chemicals like chromates or nitrites?

No, it's formulated without hazardous chromates, nitrites, or phosphate inhibitors, making it a safer option for both users and the environment.

Relevant products you may want to consider:

• How long can I expect Cortec VpCI-329 to protect metals once applied?

When properly diluted and applied, Cortec VpCI-329 offers impressive corrosion resistance, providing protection for up to 60 months.

• What is the typical shelf life of Cortec VpCI-329 if stored correctly?

You can expect a shelf life of up to 24 months for Cortec VpCI-329 when it's stored in its original, sealed packaging.

• Does Cortec VpCI-329 leave a thick, difficult-to-remove residue on surfaces?

• Are there different versions or formulations of Cortec VpCI-329 available?

Yes, besides the concentrated VpCI-329, Valdamark Direct also offers VpCI-329 D, which is a ready-to-use diluted version. There are also other specialized formulations like VpCI-329 F, ES, and SC for specific needs.

Relevant products you may want to consider:

• What packaging sizes is Cortec VpCI-329 typically available in from Valdamark Direct?

Valdamark Direct offers Cortec VpCI-329 in convenient 5-gallon (19-liter) pails and larger 55-gallon (208-liter) drums, catering to various project sizes.

• How should I store Cortec VpCI-329 to ensure its effectiveness and shelf life?

To maintain its efficacy and extend its shelf life, Cortec VpCI-329 should always be stored sealed.

• Is Cortec VpCI-329 readily available for international delivery?

Yes, Valdamark Direct explicitly states that Cortec VpCI-329 is available for international delivery.

• Are there any benefits to purchasing Cortec VpCI-329 in larger quantities?

Valdamark Direct often provides bulk buying discounts, making it more cost-effective for larger requirements.

• Does Cortec VpCI-329 have a high flash point, indicating its safety in terms of flammability?

Yes, Cortec VpCI-329 boasts a high flash point of 295°F (146°C), which is a good indicator of its safety regarding flammability.

Relevant products you may want to consider:

• Is there a specific NATO Stock Number (NSN) or military specification that Cortec VpCI-329 conforms to?

Indeed, Cortec VpCI-329 conforms to MIL-PRF-46002C (Grade 1) and also has NATO #6850-66-132-6100 and NSN #6850-01-470-3359.

• If I spill Cortec VpCI-329, what's the recommended clean-up procedure?

In case of a spill, the recommendation is to absorb the material with a sweeping compound or another absorbent material. It's crucial to prevent it from entering streams and waterways.

• How should empty containers of Cortec VpCI-329 be disposed of?

Empty drums should be properly bunged and promptly disposed of in an environmentally safe manner, adhering to all existing federal, state, and local environmental regulations. Recycling through qualified reprocessing organizations is also an option.

• Is Cortec VpCI-329 considered a hazardous material for transport?

While it's important to consult the Safety Data Sheet (SDS) for the most up-to-date and complete information, general product information indicates it has a high flash point, which can influence transport classifications. However, it's always best to refer to the official SDS for specific transport regulations.

• What are the general safety precautions I should take when handling Cortec VpCI-329?

As with most industrial chemicals, it's recommended to avoid prolonged skin and eye contact, and to avoid inhaling vapors. Always consult the Safety Data Sheet (SDS) for comprehensive safety information and personal protective equipment recommendations.

Relevant products you may want to consider:

• Does the product have any certifications or approvals related to its use in specific industries, like food processing?

While the general VpCI-329 is a broad industrial product, specific formulations like VpCI-329 F are approved for use by the US Department of Agriculture (USDA) and conform to FDA CFR 178.3300, allowing its use on packaging materials in indirect contact with meat and poultry. This indicates the versatility and acceptance of the VpCI-329 family of products for specialized applications.