Cortec VpCI® 322 Oil Based Corrosion Inhibitor Concentrate

Cortec VpCI® 322 Oil Based Corrosion Inhibitor Concentrate

Couldn't load pickup availability

VpCI® 322 is an oil based, concentrated corrosion protection solution. Cortec VpCI 322 performs well both indoor and outdoors.

Cortec VPCI technology is used in this formula. They form a thin, robust, mono layer film that attaches to metal surfaces providing outstanding contact corrosion and rust protection.

Vapour Phase Corrosion Inhibitors (VPCI) are used in the 322 formula. This provides protection in addition to the physical barrier of the film itself. The VPCI molecule essentially evaporate into the air above the corrosion inhibitor oil.

These VPCI molecules ‘cling’ to metal surfaces and can provide long term rust protection.

VPCI 322 Key Points

- Provides ‘multi-metal’ rust protection for both ferrous and non-ferrous metals.

- Barium, Chromates, Phosphate Inhibitor & Nitrate free.

- High flash point.

- High thermal stability formula. Long term contact corrosion with Vapour Phase technology.

- Will pass easily through a 5-micron filter.

- Suitable for use with hydraulics.

- Compatible with chlorides.

- VPCI 322 can be used at a 5-10% level of concentration ratio to hydraulic fluids, does not affect viscosity at lower temperatures or pour point.

- Can be used with the majority of synthetic and mineral based oils.

- Effective when used in both operating & intermittent conditions.

Typical Applications

Various hydraulic oil grades and viscosities are compatible with 322 for intermittent operational requirements. It can be added to oil in a 9 to 1 ratio, 1 x part Cortec VPCI 322 with 9 parts chosen oil.

This provides corrosion protection for up to 2 years.

Fogging cavities or inner spaces with 322 is also possible for equipment in awkward or difficult to reach places. Here consider using the 322 concentrate (1 ltr) per 35 ft³ (1.1m³) of enclosed space.

Use this method for equipment such as tanks, gearboxes, and other differentials. Either during transportation or storage.

Can be removed using an alkaline based solution such as the VPCI 414 cleaner degreaser.

Commonly used as a corrosion inhibitor in the oil and gas industry.

What metals can be protected?

- Carbon Steel.

- Magnesium.

- Stainless Steel.

- Cadmium.

- Galvanised Steel.

- Copper.

- Zinc.

- Brass.

- Silver.

- Aluminium.

- Magnesium.

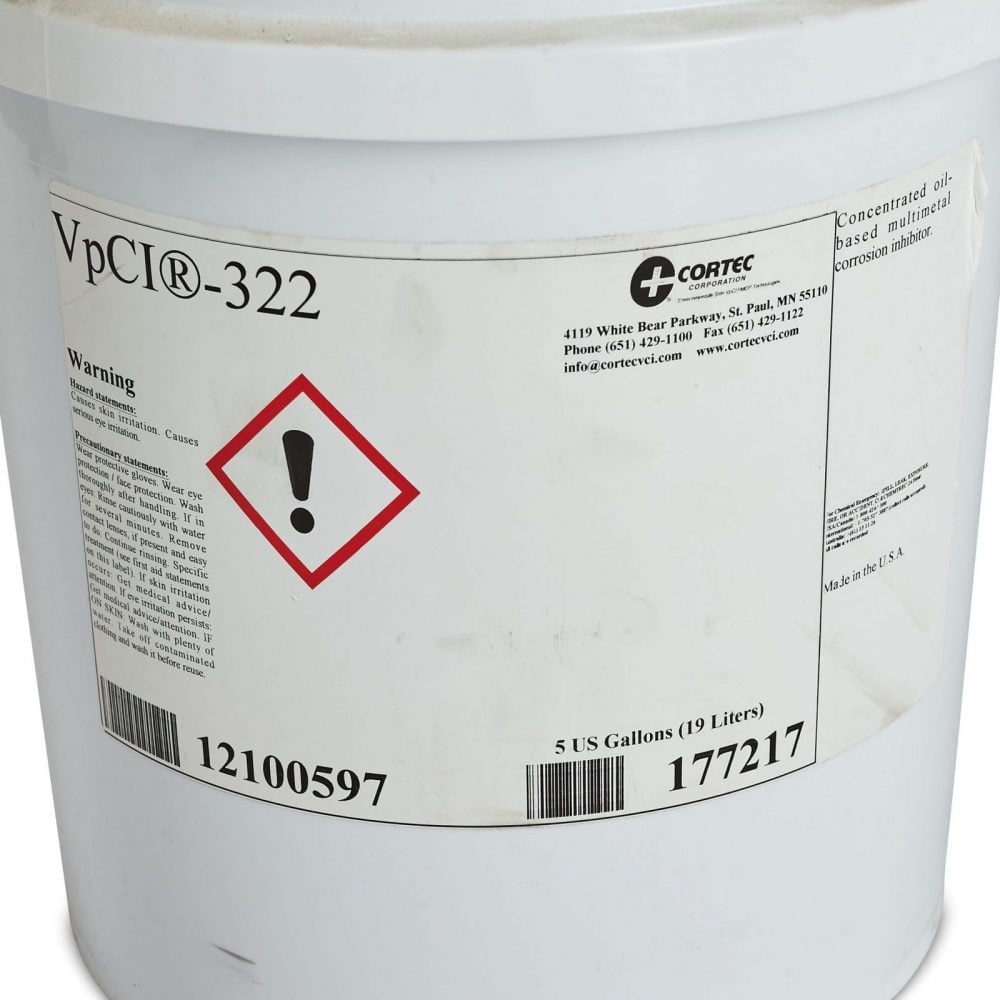

Packaging & Storage

Typically, VCPI 322 is supplied in 5 gallons (19 litre) bulk pails or 55-gallon (208 litre) bulk drums. You should ensure the product is sealed completely when not in use or being stored. VPCI 322 has a 24-month shelf life.

Product Specifications (.PDF)

Frequently Asked Questions

• What exactly is Cortec VpCI-322 and how does it protect metals?

Cortec VpCI-322 is a highly effective, oil-based concentrate specifically formulated to provide dual-phase corrosion protection. It works by forming a tenacious film on metal surfaces, offering excellent contact corrosion protection, while simultaneously releasing Vapor phase Corrosion Inhibitors (VpCIs) that travel through the air to protect inaccessible areas above the oil line.

• What's the unique dual-phase protection of Cortec VpCI-322?

The real cleverness of Cortec VpCI-322 lies in its dual-phase action. Firstly, it contains oil-soluble inhibitors that create a strong, clinging film directly on metal surfaces that are in contact with the oil. Secondly, its unique VpCI technology allows for the release of protective vapors into the air space, which then condense on all metal surfaces, even those not directly coated by the oil, providing comprehensive protection.

• Which types of metals can Cortec VpCI-322 effectively protect?

Cortec VpCI-322 is designed to offer broad-spectrum protection for a wide range of metals. This includes common ferrous metals like carbon steel and stainless steel, as well as various non-ferrous metals such as copper, brass, aluminum, galvanized steel, cadmium, magnesium, silver, and zinc.

• How long can I expect Cortec VpCI-322 to protect equipment during storage or operation?

When properly applied at the recommended dilution, Cortec VpCI-322 can provide significant corrosion protection for up to 24 months, making it an ideal solution for long-term storage or intermittent operation of machinery.

• Is Cortec VpCI-322 suitable for both indoor and outdoor exposure?

Yes, Cortec VpCI-322 is engineered to deliver excellent corrosion protection in a variety of conditions, including both indoor storage environments and situations where equipment might be exposed to open air.

Relevant products you may want to consider:

• What are the primary applications where Cortec VpCI-322 shines?

Cortec VpCI-322 is particularly effective for protecting lubricating and hydraulic oil systems, especially those that experience intermittent operation. It’s also an excellent choice for preserving tanks, gearboxes, and differentials, whether they are being stored or shipped dry.

• How do I add Cortec VpCI-322 to my existing lubricating or hydraulic oils?

For active lubricating and hydraulic oil systems with intermittent operation, you should add Cortec VpCI-322 to your existing oil at a ratio of 1 part VpCI-322 to 9 parts of the oil. This concentration helps ensure robust protection for up to 24 months.

• Can Cortec VpCI-322 be used to protect the internal cavities of dry-stored equipment?

Absolutely! For tanks, gearboxes, or differentials that are stored or shipped dry, you can effectively protect their interior cavities by fogging them with the concentrated Cortec VpCI-322. A general guideline is to use 1 quart (or 1 liter) per 35 cubic feet (or 1.1 cubic meters) of enclosed space.

• Will Cortec VpCI-322 impact the performance or characteristics of my hydraulic fluids?

A great feature of Cortec VpCI-322 is that when added to hydraulic fluids at its recommended concentration level of 5-10%, it does not negatively affect their pour point or viscosity, even in low-temperature conditions, ensuring your equipment continues to operate smoothly.

• Is Cortec VpCI-322 compatible with different types of oils, like mineral and synthetic?

Yes, this is one of its key advantages; Cortec VpCI-322 is designed to be compatible with most common mineral and synthetic oils, offering broad applicability across various industrial setups.

Relevant products you may want to consider:

• How does Cortec VpCI-322 help with intermittent equipment operation?

For equipment that runs on and off, like in a factory that has seasonal production, Cortec VpCI-322 provides continuous protection in both the liquid and vapor phases. This ensures that even when the machinery is idle, corrosion inhibitors are actively safeguarding all metal surfaces.

• Can I use Cortec VpCI-322 if chlorides are present in my system?

Yes, a notable benefit of Cortec VpCI-322 is its ability to provide effective protection even in the presence of chlorides, which are notorious for accelerating corrosion.

• What makes Cortec VpCI-322 a better choice than traditional rust prevention methods?

Unlike many conventional rust preventatives that can be messy, difficult to apply, and potentially hazardous, Cortec VpCI-322 offers a cleaner, safer, and more efficient solution. Its dual-phase protection ensures comprehensive coverage, even in hard-to-reach areas, without the need for extensive cleaning or degreasing afterwards.

• Does Cortec VpCI-322 contain any harmful or hazardous chemicals?

No, Cortec VpCI-322 is formulated without hazardous substances like barium, chromates, nitrites, or phosphate inhibitors, making it a more environmentally conscious and safer choice for your operations and personnel.

• How does Cortec VpCI-322 contribute to reducing maintenance costs?

By actively preventing corrosion for extended periods, Cortec VpCI-322 significantly reduces the need for costly repairs, part replacements, and extensive maintenance work often associated with rust damage, ultimately saving you money in the long run.

Relevant products you may want to consider:

• Will Cortec VpCI-322 leave a heavy, sticky residue on surfaces?

Cortec VpCI-322 leaves behind an oily, paraffinic film which is effective in providing corrosion protection without being excessively heavy or difficult to remove, should removal be necessary.

• Is Cortec VpCI-322 thermally stable?

Yes, Cortec VpCI-322 is designed to be thermally stable, which means its protective properties remain effective even under varying temperature conditions, ensuring consistent performance.

• Can Cortec VpCI-322 pass through filtration systems?

Yes, Cortec VpCI-322 is formulated to pass through a size 5 micron filter, ensuring it won't clog or impede your existing filtration systems when added to oils.

• What is the typical appearance of Cortec VpCI-322?

Cortec VpCI-322 typically appears as a dark amber, viscous liquid, making it easily distinguishable.

• What is the flash point of Cortec VpCI-322?

Cortec VpCI-322 has a high flash point, greater than 212°F (or 100°C), contributing to safer handling and storage.

Relevant products you may want to consider:

• How is Cortec VpCI-322 typically removed from surfaces if needed?

If removal is necessary, Cortec VpCI-322 can be effectively removed using petroleum solvents or alkaline cleaners, such as those from Cortec's VpCI-410 series.

• What is the pH level of a 1% aqueous solution of Cortec VpCI-322?

A 1% aqueous solution of Cortec VpCI-322 typically has a pH ranging from 8.5 to 10.0.

• Is Cortec VpCI-322 considered low in toxicity?

Yes, Cortec VpCI-322 is formulated to be low in toxicity, contributing to a safer working environment for those handling the product.

• What is the typical density of Cortec VpCI-322?

The typical density of Cortec VpCI-322 ranges from 7.4 to 7.6 pounds per gallon (0.89-0.91 kg/l).

• What packaging options are available for Cortec VpCI-322 from Valdamark Direct?

Valdamark Direct offers Cortec VpCI-322 in several convenient packaging options to accommodate various project sizes, including 5-gallon (19-liter) pails and 55-gallon (208-liter) drums. Larger quantities like liquid totes and bulk options are also available.

Relevant products you may want to consider:

• What is the recommended shelf life for Cortec VpCI-322?

When stored properly in its sealed container, Cortec VpCI-322 has a shelf life of up to 24 months, ensuring you have ample time to utilize the product effectively.

• How should Cortec VpCI-322 be stored to maintain its quality?

To preserve its effectiveness and shelf life, Cortec VpCI-322 should be stored in its original, tightly sealed container in a cool, dry place, away from extreme temperatures and direct sunlight.

• Where can I find the official technical data sheet (TDS) for Cortec VpCI-322?

The technical data sheet (TDS) for Cortec VpCI-322, which provides comprehensive product specifications and performance data, is typically available for download directly from the product page on the Valdamark Direct website, or by contacting their support team.

• Is a Safety Data Sheet (SDS) available for Cortec VpCI-322?

Yes, a Safety Data Sheet (SDS) for Cortec VpCI-322 is readily available to provide detailed information on safe handling, storage, emergency procedures, and environmental considerations for the product. It can usually be found alongside the product's technical data sheet.

• What is the coverage rate for Cortec VpCI-322 when applied as a film?

When applied as a film, Cortec VpCI-322 offers an impressive coverage of approximately 1260-1370 square feet per gallon (31-34 m²/l), forming a film thickness of 0.5-1 mil (12.5-25 microns).