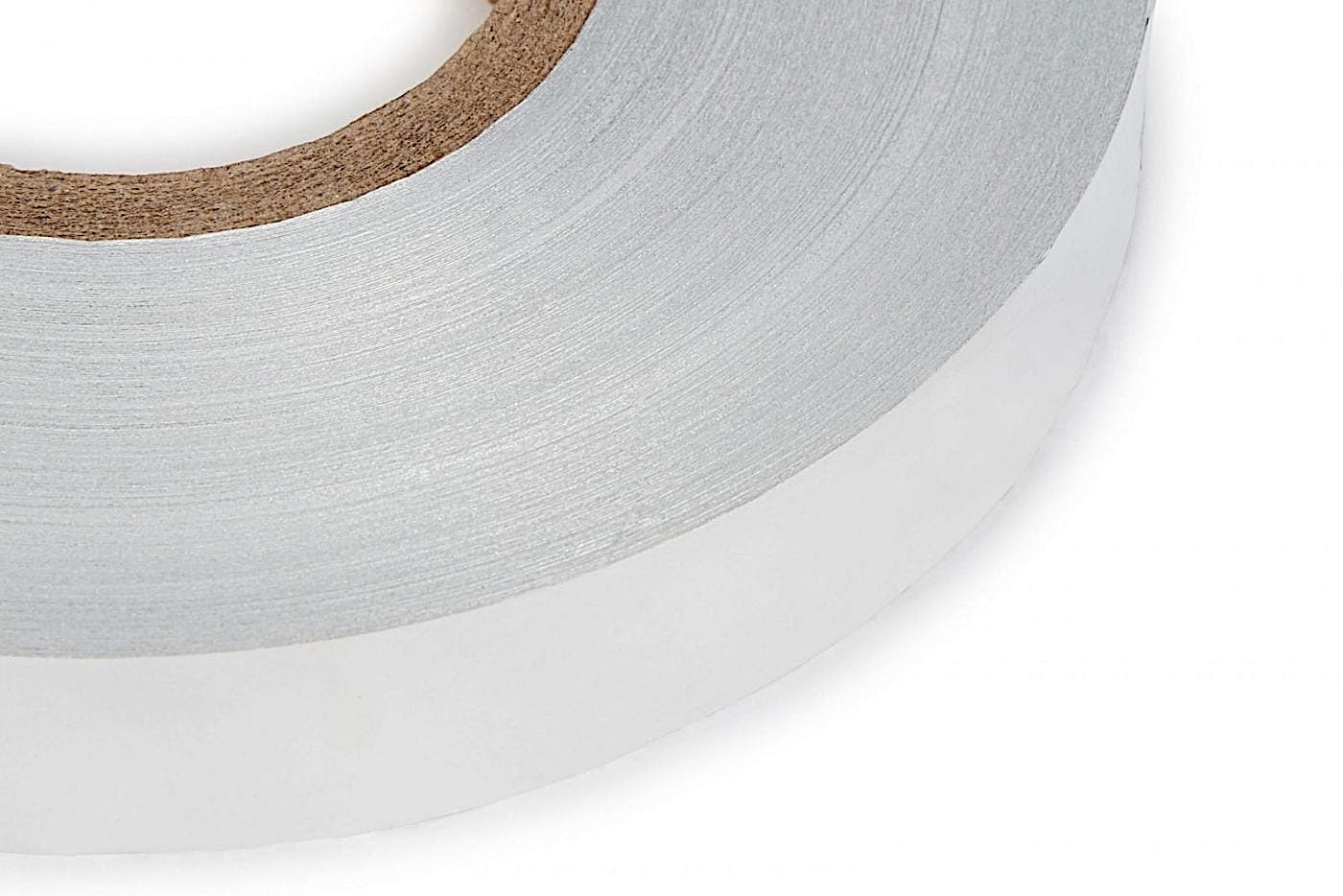

LDPE FOIL / LDPE Coated Aluminium Foil / Constructions & Sizes Made To Order

LDPE FOIL / LDPE Coated Aluminium Foil / Constructions & Sizes Made To Order

Stock TBD

Couldn't load pickup availability

- International Delivery

- Bulk Buying Discounts

- Best-in-Class Products

PLEASE NOTE – Valdamark Ltd does not supply LDPE film as a raw material.

Our LDPE Foil constructions are ‘coated’ where LDPE is one component layer of a thicker, multi layered material. Usually a 3 ply material but some laminate in our range feature 5 or 6 PLY (independent layers).

Valdamark LDPE Foil conversions are made to order in line with the end users requirements.

Our custom extrusion and lamination manufacturing capabilities allow us to produce LDPE Foil constructions to a clients exact specification. Our finished products are of a consistently high quality with a narrow production tolerance.

LDPE (low density polyethylene) is used as a standalone or component layer in many thermoplastic films, With many desirable mechanical properties and characteristics LDPE foils use is widespread. Manufactured in transparent or opaque variations LDPE displays excellent chemical resistance and resilience properties.

Weather you are looking for a simple LDPE based commodity film or a more technical LDPE containing multi-layers, we can likely tailor a solution for your needs.

We cater to a wide variety of markets and sectors. LDPE Foil’s for high usage projects are a speciality.

Sectors we serve include:

- Transport & Storage.

- Industrial Packaging.

- Medical, Healthcare and Pharmaceutical Sectors.

- Food Production.

- Agrofoods & Agricultural.

- Aerospace and Aviation Packaging.

- Chemical and Nuclear.

The majority of our clients operate in heavily regulated markets. Food contact materials in line with EU regulations & Directive 1935 2004 (CE 1935 2004) is often the key requirement for any LDPE foil used in a food production & packaging environment. We have film constructions that are both compatible with this and other food packaging regulations.

- Multi layer high barrier films with a low moisture vapour transmission rate.

- ESD, Anti static films.

- VCI & VpCI impregnated constructions.

- Excellent mechanical properties. High tear & puncture resistance.

- Full conformity to US MIL SPEC, UK DEF STAN, French NF & German DIN military standards.

- FDA, Pharmacopeia (ISO 7) as well as food contact approved films.

Valdamark produce LDPE Foil in a variety of bespoke slit/cut to order rolls

For projects that require a more robust foil packaging take a look at our full range of both standard and made to order formats.

Frequently Asked Questions

• What exactly is LDPE foil and why is it a popular choice for packaging?

LDPE foil, or Low-Density Polyethylene foil, is a versatile and commonly used thermoplastic film known for its exceptional flexibility, transparency, and durability. It's a popular choice for packaging because it offers a reliable barrier against moisture, provides excellent protection for various goods, and is relatively cost-effective.

• How is Valdamark Direct's LDPE foil different from other plastic films?

Valdamark Direct's LDPE foil stands out due to its specific properties: it's highly flexible, boasts a low melting point for easy processing, and offers good resistance to many chemicals. Unlike some other plastics, it maintains its integrity well in a range of temperatures, making it adaptable for diverse applications.

• Is Valdamark Direct's LDPE foil considered environmentally friendly?

Yes, Valdamark Direct's LDPE foil is recyclable. While local recycling facilities may have varying acceptance policies for flexible films, LDPE is a thermoplastic that can be processed and reused, contributing to a more circular economy and reducing reliance on virgin materials.

• What does "low-density" mean in the context of LDPE foil, and why is it important?

"Low-density" refers to the specific molecular structure of the polyethylene, which results in a material that is more flexible, less rigid, and has a lower melting point compared to high-density polyethylene (HDPE). This low density is crucial for applications requiring stretchability, excellent sealing properties, and a softer feel, such as in many packaging films.

• What kind of transparency can I expect from Valdamark Direct's LDPE foil?

Valdamark Direct's LDPE foil offers excellent clarity, making it an ideal choice for packaging where product visibility is important. This transparency ensures that contents are easily identifiable without compromising the protective qualities of the film.

Relevant products you may want to consider:

• For what types of products is Valdamark Direct's LDPE foil best suited for packaging?

Valdamark Direct's LDPE foil is incredibly versatile and is ideal for packaging a wide array of products, including food and beverages, pharmaceuticals, consumer goods like electronics and clothing, and various industrial components. Its protective qualities make it suitable for items needing defense against moisture, dirt, and mechanical damage.

• Can Valdamark Direct's LDPE foil be used for long-term storage of goods?

Yes, Valdamark Direct's LDPE foil provides a durable and protective barrier that is suitable for long-term storage, safeguarding products from dust, moisture, and other environmental contaminants. For items requiring even greater protection, it can also be used in conjunction with other barrier materials.

• Is Valdamark Direct's LDPE foil effective for industrial packaging, such as machinery parts?

Absolutely. Valdamark Direct's LDPE foil is widely used in industrial settings for packaging and protecting machinery, components, and other heavy-duty goods during transport and storage. Its durability and puncture resistance make it a reliable choice for these demanding applications.

• Can I use Valdamark Direct's LDPE foil for food packaging applications?

Yes, Valdamark Direct's LDPE foil is safe for food contact applications and is frequently used in the food industry to package fresh produce, baked goods, and frozen items. Its ability to maintain freshness and its non-toxic properties make it a reliable choice for food preservation.

• How does Valdamark Direct's LDPE foil perform in cold environments, such as for frozen goods?

Valdamark Direct's LDPE foil exhibits excellent cold-storage capabilities. It retains its flexibility and protective qualities even in freezing temperatures, making it an ideal solution for packaging frozen foods and other products that require cold chain logistics.

Relevant products you may want to consider:

• Is Valdamark Direct's LDPE foil suitable for creating protective wraps for pallets during shipping?

Yes, LDPE is a common material for shrink wrap and stretch film applications, which are used to secure and protect pallets of goods during shipping and transit. Valdamark Direct's LDPE foil, given its flexibility and strength, is well-suited for this purpose, helping to prevent damage and shifting of items.

• Can Valdamark Direct's LDPE foil be used as a moisture barrier in construction or DIY projects?

While the primary focus of Valdamark Direct's LDPE foil is packaging, LDPE sheeting in general is widely used in construction and DIY as a moisture and dust barrier. Its inherent moisture resistance makes it a practical material for such applications, though specific product thickness would dictate suitability.

• What is the typical thickness range available for Valdamark Direct's LDPE foil?

Valdamark Direct offers LDPE foil in various thicknesses to accommodate different packaging needs. While exact specifications may vary by product variant, LDPE films generally range from thin films for light packaging to thicker gauges for more robust applications, offering versatility for diverse projects.

• How do I effectively seal Valdamark Direct's LDPE foil for secure packaging?

Valdamark Direct's LDPE foil can be effectively heat-sealed. For optimal seal strength, an impulse sealer is recommended, with typical temperature ranges between 145°C - 185°C (239°F - 365°F) for approximately 0.1 to 3 seconds, depending on the film's thickness.

• Does Valdamark Direct's LDPE foil offer good resistance to punctures and tears?

Yes, despite being flexible, Valdamark Direct's LDPE foil is formulated to offer good resistance to punctures and tears, providing a robust protective layer for packaged goods, even those with irregular shapes or sharp edges.

Relevant products you may want to consider:

• Is Valdamark Direct's LDPE foil resistant to chemicals?

Valdamark Direct's LDPE foil exhibits resistance to many common chemicals, making it suitable for packaging various substances without concern for degradation of the film or contamination of the contents.

• Does Valdamark Direct offer different colors or custom printing options for its LDPE foil?

While specific stock options vary, LDPE foil is generally amenable to customization, including being dyed in various colors and printed with branding, logos, or product information. Customers with specific needs for custom colors or printing on Valdamark Direct's LDPE foil should inquire directly with their sales team.

• What are the main advantages of choosing Valdamark Direct's LDPE foil over other packaging materials?

The key advantages of Valdamark Direct's LDPE foil include its high flexibility, excellent clarity, superior moisture resistance, good impact and puncture resistance, and cost-effectiveness. It's also lightweight, which can contribute to reduced shipping costs, and its versatility makes it suitable for a vast range of applications.

• How does using Valdamark Direct's LDPE foil contribute to cost efficiency?

Valdamark Direct's LDPE foil contributes to cost efficiency through its relatively low manufacturing cost, lightweight composition that reduces freight expenses, and its ability to minimize product loss due to damage during handling and transit, ultimately improving overall logistical efficiency.

• Can Valdamark Direct's LDPE foil be integrated with automated packaging systems?

Yes, LDPE films are designed to integrate smoothly with automated packaging systems, which can significantly improve warehouse productivity and lead to quicker packaging turnaround times for businesses.

Relevant products you may want to consider:

• Does Valdamark Direct's LDPE foil offer any branding or customization opportunities?

Absolutely. Valdamark Direct's LDPE foil provides a high-quality surface that is receptive to vibrant printing. This allows businesses to customize bags with their company logos, barcodes, or compliance information, effectively enhancing brand visibility and meeting regulatory standards.

• What are the benefits of the flexibility of Valdamark Direct's LDPE foil for packaging irregular items?

The inherent flexibility of Valdamark Direct's LDPE foil allows it to conform easily to various shapes and sizes, making it exceptionally adaptable for packaging irregularly shaped items that might be challenging for more rigid packaging materials.

• How does Valdamark Direct's LDPE foil contribute to product integrity during transport?

Valdamark Direct's LDPE foil, with its robust and durable nature, significantly reduces the risk of products being damaged during handling and transit. This contributes to better product integrity upon arrival, leading to higher customer satisfaction and fewer returns.

• How does Valdamark Direct's LDPE foil compare in performance to HDPE (High-Density Polyethylene) films?

While both are polyethylenes, Valdamark Direct's LDPE foil is more flexible, transparent, and generally less rigid than HDPE. This makes LDPE better suited for applications requiring high clarity and stretchability, whereas HDPE is often preferred for stiffer, more rigid applications like bottles and pipes.

• Is Valdamark Direct's LDPE foil suitable for specialized applications requiring anti-static properties?

While the standard LDPE foil from Valdamark Direct might not inherently possess anti-static properties, specialized LDPE films can be manufactured with anti-static additives for packaging sensitive electronics. It's best to confirm specific requirements with Valdamark Direct.

Relevant products you may want to consider:

• What is the typical shelf life of goods packaged in Valdamark Direct's LDPE foil?

When properly sealed and stored, products packaged in Valdamark Direct's LDPE foil can maintain their integrity and freshness for extended periods, as the film acts as an effective barrier against external elements that could compromise shelf life.

• Can Valdamark Direct's LDPE foil withstand varying temperature fluctuations during shipping?

Yes, Valdamark Direct's LDPE foil is designed to perform reliably across a wide range of temperatures, from extreme heat to freezing cold. This temperature resilience is a key advantage, making it a dependable solution for shipping products across diverse climates.

• What types of roll or sheet formats is Valdamark Direct's LDPE foil available in?

Valdamark Direct typically offers LDPE foil in large rolls, often referred to as 'sleeves' or 'tunnels', making them suitable for machine packaging and for customers who wish to cut the material to their specific requirements on-site. Specific formats and dimensions can be discussed with their team.

• How can I obtain a sample or request a quote for Valdamark Direct's LDPE foil?

To obtain samples or request a tailored quote for Valdamark Direct's LDPE foil, it is best to directly contact the Valdamark Direct sales team through their website or by phone, as they can provide personalized assistance based on your specific project needs.

• What kind of technical support does Valdamark Direct offer for its LDPE foil products?

Valdamark Direct is known for providing comprehensive technical support for its packaging solutions, including LDPE foil. They can offer guidance on product selection, application methods, sealing parameters, and address any specific performance or compliance questions you may have.