Heat sealers are incredibly important for a wide range of businesses, particularly commercial heat sealers. Both rotary band sealers and impulse sealers regularly prove their value to businesses of all kinds.

Here at Valdamark, we’re often asked if it’s possible to use domestic heat sealers to make your own plastic bags. The answer is yes, but there are a few things you need to know before you get started.

First of all, if you’re going to make your own plastic bags, you need to be aware that they won’t be suitable for a lot of commercial use. If you want to professionally package your commercial products or medical equipment, you need to use proper packaging materials, such as VCI bags.

Make Your Own Sealed Bags With A Heat Sealer

If you’re going to be making your own plastic bags using layflat tubing, the first thing you need to consider is the type of bag you want to make. There are two main types of bag: those with a flat bottom, and those with a gusset.

If you want to make a flat bottomed bag, the process is relatively simple. You just need to heat seal the tubing at the bottom, and then cut it to size.

If you want to make a gusseted bag, the process is a little more complicated. You need to create a fold in the tubing, and then heat seal it. This will create a ‘gusset’ in the bottom of the bag, which will allow it to stand up by itself.

Once you’ve decided on the type of bag you want to make, the next thing you need to consider is the size. Again, this will depend on what you’re going to be using the bags for.

If you’re unsure of what size you need, it’s always best to err on the side of caution and go for a larger size. You can always cut the bag down to size once it’s been sealed, but you can’t make a smaller bag bigger!

Almost Limitless Customisation Options For Your Own Heat Sealed Plastic Bags

If you have a heat sealer with a cutter, you can make almost any size or thickness of plastic bag. All you need is a roll of polythene layflat tubing!

You can buy this tubing in a variety of widths, from 50mm up to 1500mm. The most popular widths are 250mm and 500mm.

The thickness of the tubing will also vary, depending on what you need the bags for. You can buy tubing that’s between 25 microns and 200 microns thick.

When you’re customising your heat sealed plastic bags, here’s a step-by-step process you can use to create the perfect size of plastic bags for you:

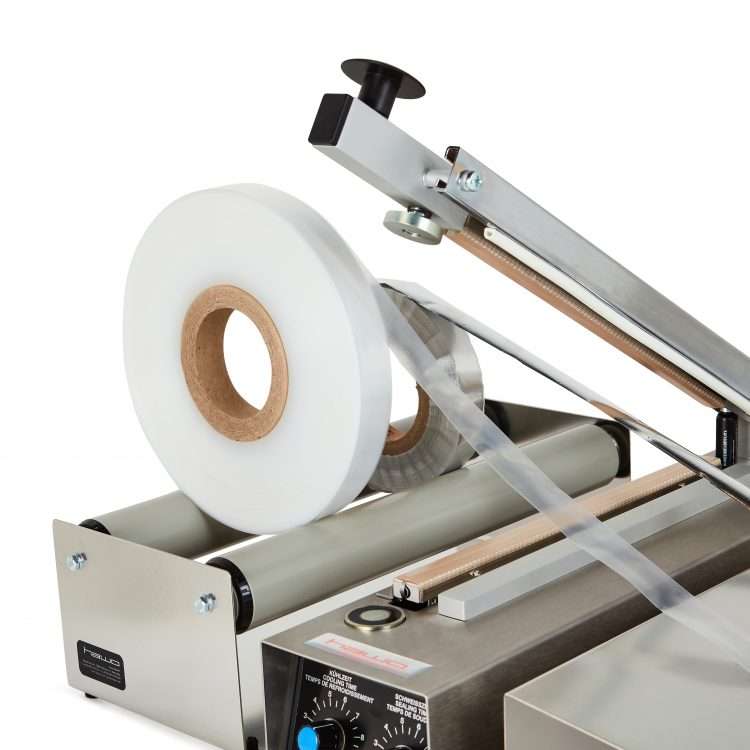

- Feed the layflat tubing into the heat sealer machine.

- Engage your heat sealer, whether it’s a clip or arm-operated impulse sealer.

- What until the heat sealer has sealed the layflat tubing together.

- Use the built-in heat sealer cutter to separate your newly-made bag from the roll.

- Fill the bag with your chosen product – bear in mind that your product won’t be as protected as if you chose a pre-made VCI bag.

- Seal the other end using the heat sealer.

Choosing the Right Heat Sealer For You

The next thing you need to do is choose the right type of heat sealer for the job. For making your own plastic bags, we recommend using an impulse sealer. These are incredibly easy to use, and they give a nice, clean seal.

If you’re going to be using your heat sealer a lot, it’s worth investing in a good quality one. Here at Valdamark, we sell a wide range of impulse sealers, so you’re sure to find one that’s perfect for your needs.

Once you’ve got your heat sealer and layflat tubing, you’re ready to start making your own plastic bags! Just follow the instructions above, and you’ll have your very own custom made bags in no time.

For more information on our complete range of domestic and commercial heat sealers, don’t hesitate to get in touch today!